Introduction

The global construction industry is rapidly adopting modern technologies. It offers faster, safer, and more durable building solutions. Instead of bricklayers stacking blocks one by one, site workers are assembling what looks like giant aluminum puzzle pieces. Mivan construction is a building method that’s quietly revolutionizing how they put up everything from apartment towers to housing complexes.

What is Mivan construction? This article breaks it down simply. How does the process function step by step? One key point stands out early. Benefits show up clearly when compared to older methods. Yet there are drawbacks too—important ones. Builders everywhere now lean toward this system instead of basic brickwork. Why that shift happens comes down to practical reasons.

What Is Mivan Construction?

Solid buildings rise when workers pour concrete into reusable aluminum molds. These aren’t temporary setups; they lock together, shaping entire floors at once. Walls flow into ceilings without weak seams showing up later. You won’t find shaky joints where pieces meet. The whole thing stands tight, built to last through years of wear.

The name comes from a European company, “Mivan Construction Technology,” which started as an aluminum formwork method they created. Builders across the globe now use it to construct solid buildings.

Apart from regular construction, traditional methods treat walls, floors, and beams as separate elements built at different times. Mivan Construction casts them all together in one go, creating what engineers call a monolithic structure. Think of it like the difference between assembling Lego blocks versus molding a solid action figure. Both work, but one is inherently stronger.

Also Read: Advanced Technology in Construction: Building the Future in 2030

How Mivan Construction Technology Works?

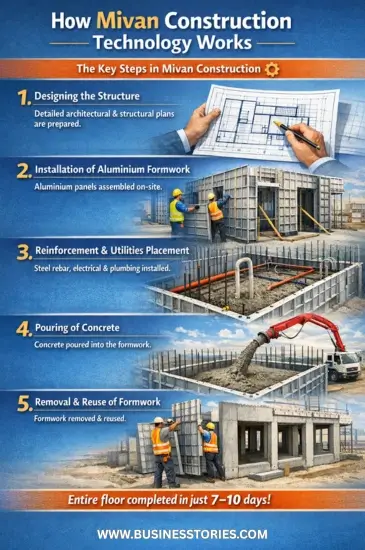

Mivan construction follows a highly organized workflow. Below are the key steps involved:

1. Designing the Structure

Everything starts with detailed blueprints. Since Mivan uses set dimensions, adjusting things afterward isn’t simple. The design phase needs to nail down every measurement upfront.

2. Installation of Aluminium Formwork

Lightweight aluminum panels are assembled on-site to shape the structure of walls, slabs, staircases, and beams. Built from aluminum, each piece holds up well under pressure. Repeated use does not wear them down. Precision comes naturally due to their firm design.

3. Reinforcement and Utilities Placement

Steel reinforcement bars are placed inside the formwork. Right after, electric channels get set in place—plumbing lines too, along with any needed service tubes. It’s all done in advance, which saves a ton of time later.

4. Pouring of Concrete

Pouring begins with top-grade concrete sliding into aluminum forms. Smoothly it moves, reaching each edge without gaps—this builds consistency through sheer fill. A dense, even shape takes form as material settles deep inside. There’s no guesswork here—the formwork ensures consistency.

5. Removal and Reuse of Formwork

Once the concrete hardens, the aluminum formwork is removed and reused for the next cycle. That keeps building steadily, without slowdowns. This cycle keeps rolling, which is why you can finish an entire floor in about a week to ten days.

Because of this well-planned cycle, an entire floor can be completed in just 7–10 days. You start seeing why builders get excited about this workflow.

Key Features of Mivan Construction

Some of the most notable characteristics of Mivan Construction include:

- A monolithic structure that increases stability. When walls and slabs are cast together, there are no weak points where different elements meet. The entire building functions as a single, unified structure, which is particularly beneficial for earthquake resistance.

- High-dimensional accuracy due to precision formwork. Those aluminum panels are manufactured to exact specifications. You’re not relying on a mason’s eye to keep walls straight—the formwork handles that automatically.

- Smooth wall finish, reducing the need for plaster. Forget about uneven walls that require multiple layers of plaster to conceal imperfections. Mivan walls are smooth enough that you can often just paint directly over them.

- Uniform wall thickness across the building. Ever noticed how in older buildings, walls seem thicker in some spots than others? Doesn’t happen with Mivan. You get uniform thickness throughout.

These features make it suitable for modern construction demands around the world.

Advantages of Mivan Construction

1. Faster Construction Timeline

Speed stands out when using Mivan construction. Compared to conventional methods, construction time can be reduced by 50% or more. Finishing sooner means workers spend fewer days on-site, which brings total labor expenses down.

2. Strong and Durable Buildings

Few materials match the toughness of Mivan builds since concrete forms walls, floors, and slabs as one solid unit. Because everything hardens at once, resistance to shifting grows stronger from within. This monolithic design provides superior structural stability.

3. Excellent Surface Quality

Smooth, precise walls come from Mivan methods, so less plastering is needed later. Finishing takes fewer steps because of how exact the surfaces turn out.

4. Lower Maintenance in the Long Term

Since the structure has fewer joints and cracks, maintenance and repair needs are significantly lower over time. Over a building’s lifetime, that translates to serious savings on repairs.

5. Cost-Effective for Large-Scale Projects

The aluminium formwork can be reused many times, making it highly economical for big residential and commercial developments.

Mivan Construction vs Brick Construction

Starting off, Mivan construction versus brick construction shows distinct contrasts in pace, consistency, and function. Building with brick construction takes time—each unit set individually slows progress. This approach leans on experienced workers; human effort can bring lopsided surfaces, fractures, and leaks. Though layout options exist freely with bricks, maintaining a uniform standard across floors proves tough.

On the flip side, Mivan Construction builds things more quickly while keeping consistency high. Because slabs and walls go up at once, forming a single unit, strength gets a real boost. That unified shape handles earthquakes better, adding safety without fuss. A clean surface comes out naturally, so there is less scraping or patching afterward. Repetitive designs benefit most, like apartment blocks or housing clusters, where the layout repeats floor after floor.

Brick buildings let you tweak room shapes more easily. Although brick construction gives the freedom to change room layouts, it still cannot match the speed, precision, and long-term strength offered by Mivan Construction.

Limitations of Mivan Construction

Even though Mivan offers several advantages, it also has a few limitations:

1. High Initial Cost

The startup cost hurts. Buying or even renting aluminum formwork requires significant capital. For a small builder doing one or two houses, it simply doesn’t make financial sense.

2. Limited Flexibility in Design

Design flexibility disappears. Once you’ve committed to a particular layout and ordered formwork for it, you are locked in. When the blueprint locks in, shifting core elements gets tricky fast.

3. Requires Highly Skilled Planning

You need people who know what they’re doing. A mistake early on might ripple through every part of the build. Precision in layout, calculations, and oversight keeps everything on track. You need proper training, careful planning, and tight coordination. Mistakes in formwork assembly or concrete pouring can affect the entire structure.

Despite these limitations, Mivan construction remains highly effective for large and repetitive building projects.

Also Read: Top 10 Construction Companies in India You Should Know

Why Is Mivan Construction Popular?

1. Fast-Growing Global Construction Needs

Big cities with growing populations are perfect for Mivan. When you need to house thousands of people quickly, this technology delivers. That’s why you see it dominating markets in India, the Middle East, and Southeast Asia. It allows projects to be completed in less time while maintaining consistent construction standards.

2. Ideal for High-Rise and Mass Housing

Mivan construction is widely used for towers, condominiums, and large residential communities. Since it offers uniform quality and quick completion, it is especially suitable for high-rise buildings and mass housing projects with repetitive floor layouts.

3. Strong and Safe Structures

When built with Mivan forms, structures stand strong under heavy loads because they act as one solid unit. Because of that unity, shaking during quakes causes less damage. These traits allow them to last across regions where weather shifts often or tremors strike. Safety doesn’t fade over time—strength stays locked in place. This makes Mivan construction suitable for different climatic and seismic zones, ensuring long-term safety and durability.

4. Sustainable and Efficient

Starting fresh each time, old materials pile up less because metal molds get used again. It reduces material waste through reusable aluminum formwork and minimizes the need for frequent repairs. Because of fewer breakdowns, fixing things every few weeks fades into the past. These factors make it a more sustainable and eco-friendly option compared to traditional construction methods.

Is Mivan Construction Suitable for Small Projects?

When projects repeat often, Mivan works fast. Efficiency shows best on big builds.

For small, single-family homes, the high cost of aluminum formwork may not be practical. However, in gated communities or townhouses with repeated layouts, it can be an excellent choice.

Future of Mivan Construction

Tall buildings rise as more people fill cities. Where space shrinks, speed in building matters most. One method stands out—Mivan Construction forms walls and floors at once. This system builds whole blocks faster than the old ways. With demand rising, it fits well where time cannot wait. Mivan Construction is expected to play a major role in the future of modern infrastructure worldwide.

Dubai and Singapore are already benefiting from their advantages. Concrete poured into aluminum molds creates solid units quickly. Labor requirements drop when parts repeat often. Less waste appears on sites that run tight schedules. Long-term savings show up even if the setup feels steep. Builders notice minimal delays when the weather bites hard.

Factories supply panels while foundations are set below. Progress marches forward without pausing too long. Safety improves with less manual lifting each day. Mistakes fade when pieces come pre-shaped correctly.

Mivan represents where things are headed—toward industrialized, standardized building processes that emphasize speed and consistency without compromising on quality. As cities keep growing upward and housing demands keep intensifying, methods like this aren’t just nice to have. They’re necessary.

We’re already seeing innovations built on the Mivan concept. Some companies are developing even lighter formwork materials. Others are integrating digital planning tools that optimize the entire process from design to completion.

Conclusion

Buildings today take shape faster because of Mivan Construction. Not just quick, but solid, precise, and still standing strong years later—this method beats laying bricks by hand. residential towers, office spaces, and mass housing projects —all come together without surprises. Performance stays steady; outcome stays dependable.

Start with a fresh look at Mivan construction – knowing its process gives clear insight. Builders see benefits when they study how it fits together quickly. Buyers notice stronger walls once the work finishes. Developers compare results across countries where time saves money. Long-term performance stands out in busy cities. Modern buildings rise faster without losing quality. Choices improve when facts replace guesswork.

Understanding what Mivan construction is, how it works, and its global advantages helps builders, buyers, and developers choose better construction methods for long-lasting and modern structures.